Hot Taps or Hot Tapping is a technique to safely tie an assembly such as a sample probe into a pressurized system, by drilling or cutting, while it is on stream and under pressure.

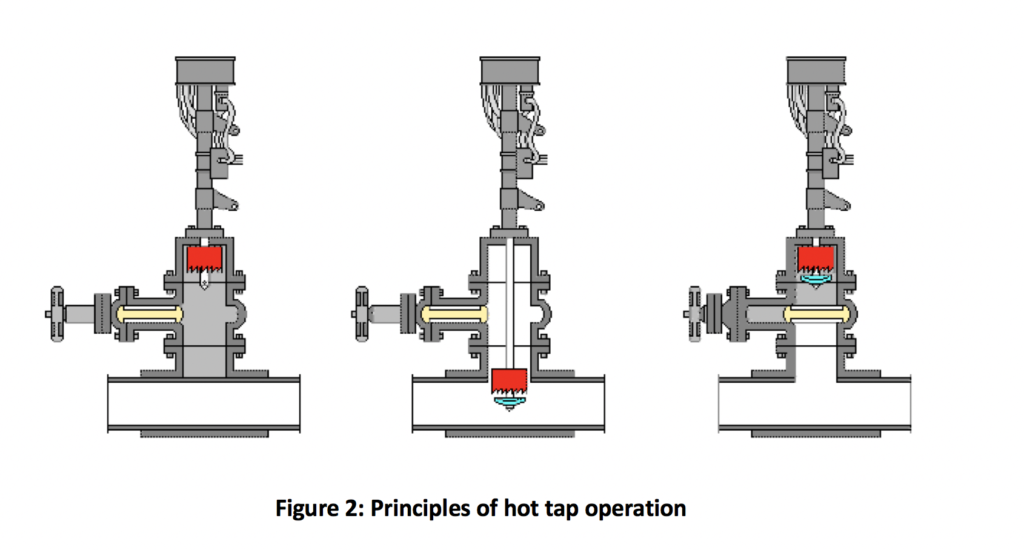

How it Works

For a hot tap, there are three key components necessary to safely drill into a pipe; the fitting, the valve, and the hot tap machine.

The fitting is attached to the pipe, usually by welding. In many cases, the fitting is a Weldolet® where a flange is welded onto the process stream.

(Image credit to wermac.org)

Onto this fitting, a valve is attached, and the hot tap machine is attached to the valve.

The hot tap cutter is a specialized type of hole saw, with a pilot bit in the middle, mounted inside of a hot tap adapter housing.

The hot tap cutter is attached to a cutter holder so that it fits into the inside of the tapping adapter.

The tapping adapter will contain the pressure of the pipe system, while the pipe is being cut, it houses the cutter, and cutter holder, and bolts to the valve.

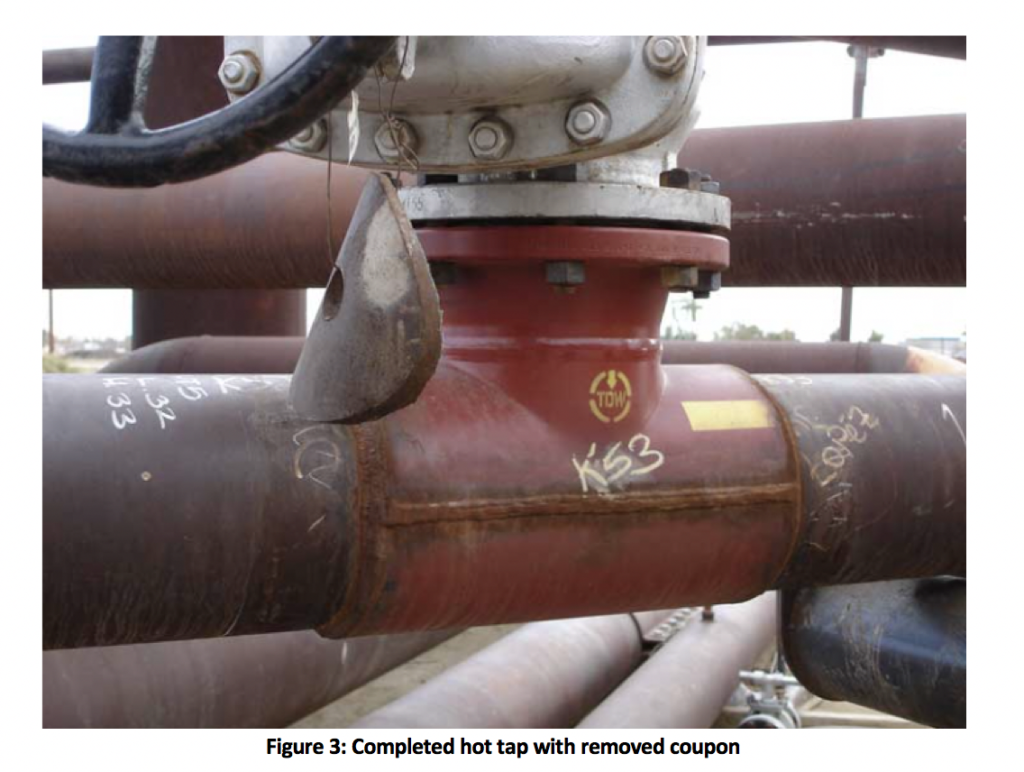

The Hot Tap is made in one continuous process, the machine is started, and the cut continues, until the cutter passes through the pipe wall, resulting in the removal of a section of pipe, known as the “coupon”.

The coupon is normally retained on one or more u-wires, which are attached to the pilot bit. Once the cutter has cut through the pipe, the hot tap machine is stopped, the cutter is retracted into the hot tap adapter, and the valve is closed.

Pressure is bled off from the inside of the Tapping Adapter, so that the hot tap machine can be removed from the line. The machine is removed from the line, and the new service is established.

(Image credit to wermac.org)

(Image credit to wermac.org)

Hot taps are used in the industry whenever systems cannot be isolated to install new equipment.

Advantages

Allows systems to be installed without process isolation

Does not require a system shutdown

Only fixed flange probes can be installed with this operation

Limitations

Requires risk assessment

Can only be performed by skilled personnel

Retractable and Fixed flange dual sample and return probes cannot be installed with this operation

Go Deeper

Case study

No case study available at this time.

Sample probes are required to be installed into a flare line to extract a sample for analysis to understand the gas composition