If the flow of gas to flare stack stops there is a possibility of air ingress into the flare stack and knock-out drum. This can result in an explosive mixture of air and hydrocarbons in the flare network, which can be catastrophic.

An effective way to avoid air ingress into the flare stack is to continuously purge a small flow rate of gas. This continuous flow into the flare network helps to build up some positive backpressure at the knock out drum (KOD). This is the normal operating pressure KOD when no other sources (relief valves, blowdown valves etc.) are emitting any relief flow.

The use of hydrocarbons for purge gas can be replaced by use of nitrogen, reducing the amount of potentially unburnt hydrocarbons as a source of methane.

How it Works

The use of fuel gas in flare headers for purging purposes results in environmental emissions. These can be in the form of CO2 or NOx when the fuel gas used in the flare headers is burnt or in the form of CH4 if not properly combusted and released in the atmosphere.

Replacing hydrocarbon fuel gas with nitrogen for purging the flare headers is an option to reduce environmental impact. The purge rate calculation required to ensure safe operations is defined on API Standard 521 and differs whether you use hydrocarbon gases or nitrogen.

A wide range of technologies and vendors are available for nitrogen generation. Nitrogen is used for a range of other seal and fire retardant roles.

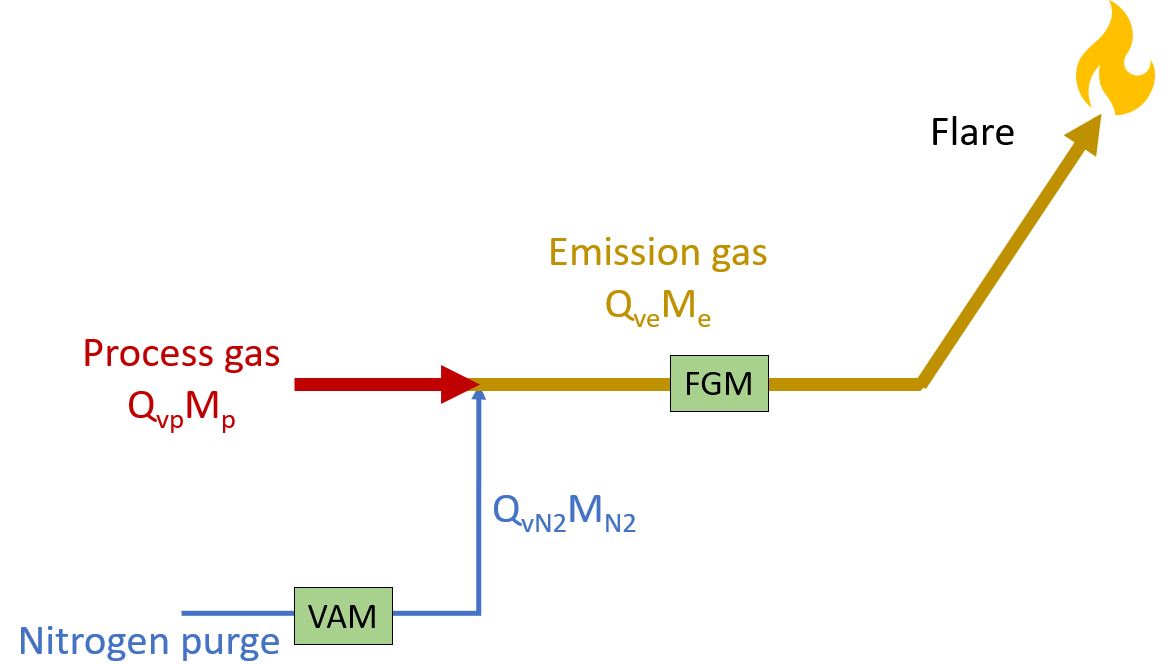

Here is a schematic of nitrogen purging:

Advantages

Reduces potential for unburnt hydrocarbons

Limitations

Requires a reliable source of nitrogen and associated poser demands

May lead to increased formation of other environmental pollutants such as NOx

Case study

Awaiting copyright approval

Flares are a safety device and many designs require the flare to remain permanently lit. To ensure that there is no ingress of air into the system (which may lead to an explosion) a minimum amount of gas passing through the flare is required. This purge gas is part of safe and reliable operations. For flares that spend extended periods in this standby state the amount of gas consumed is a significant contributor to overall emissions including methane. This may be reduced in a range of flare designs.