Computational Fluid Dynamics (CFD) modelling simulates combustion in the flare. It can be used to find the optimum flare operating envelope, including assessing performance from changes such as the composition of the gas and identify other flare performance issues such as the impact of varying wind speeds. CFD negates the need for complex empirical tests and can be used to simulate weather conditions in harsh environments (such as storms) that would be hard to replicate in other ways. CFD models require access to advanced computing facilities and expert users to ensure that model is an accurate reflection of real-world conditions.

The partial differential equations that govern fluid flow and heat transfer are highly non-linear and must be solved numerically. Therefore, in order to analyze fluid flows, flow domains are split into smaller sub domains. The governing equations are then numerically discretized and solved inside each of these subdomains. The subdomains are often called finite volumes, elements or cells, and the collection of all elements is called a mesh.

Each cell reports values of pressure, velocity and other physical properties that allow heat maps and streamlines to be constructed to visualize the flow field.

By applying CFDis a branch of fluid mechanics that uses numerical analysis and data structures to analyse and solve problems that involve fluid flows. Computers are used to perform the calculations required to simulate… Learn more… modelling and the knowledge of combustion chemistry, it is possible to simulate the combustion at the flare tip to estimate the combustion and destruction efficiencies and measure flare performance from other perspectives (flame stability, flashback, etc.)

Advantages

Possibility to model any flare type, with/without assist features, any fluid composition

Helps identify optimal flare purge ratesThe flowrate of flare purge gas Learn more... at different wind conditions

Can be used as a tool for design of new flares as well as operations troubleshooting for existing systems. It can support optimisation in terms of combustion, destruction efficiency and other flare performance parameters

It can identify hazardous scenarios where flame flashback or formation of explosive mixture in the flare system is possible

Can be used to train data driven digital twin models of flares to support more efficient operation

Limitations

Steady-state simulation provides a time-averaged solution, however, may not always reflect the transient turbulent mixing. Transient simulations, capturing most turbulence effects could be performed, yet is much more resource intensive.

Flare tip may sustain defects or deformation during operations, which can introduce discrepancies between the actual operating performance and CFD model if it is based on a new flare tip

Would require additional modelling to factor in precipitation (rain, snow) effects on combustion

Liquid entrainment in flared gas stream affects the combustion, yet it requires more complex modelling and is less well understood, hence, most models are based on single-phase gas flow.

Access to advanced computing capability to reduce the time taken to run models

Limited validation data available comparing model outputs to physical observations

Case study

Assessing the impacts of wind speed on an offshore flare system

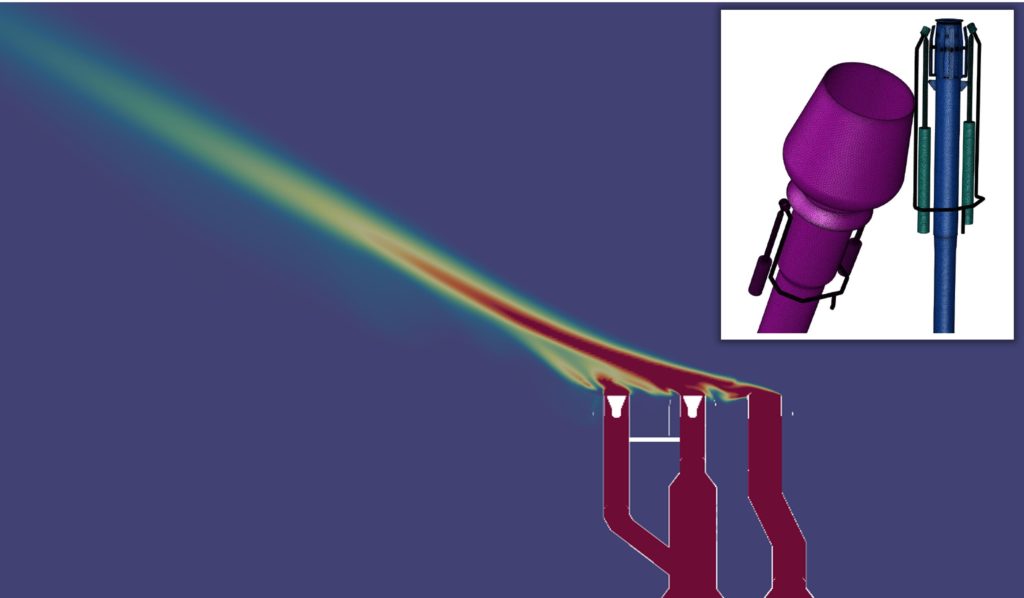

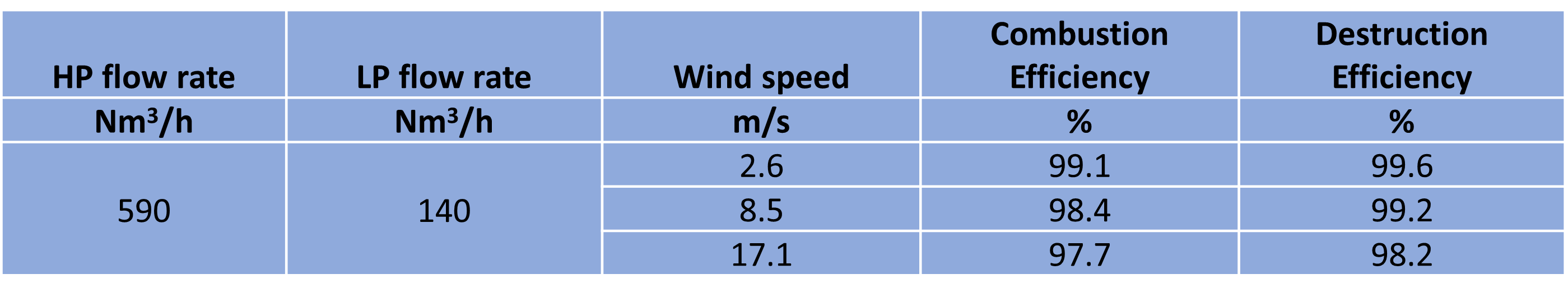

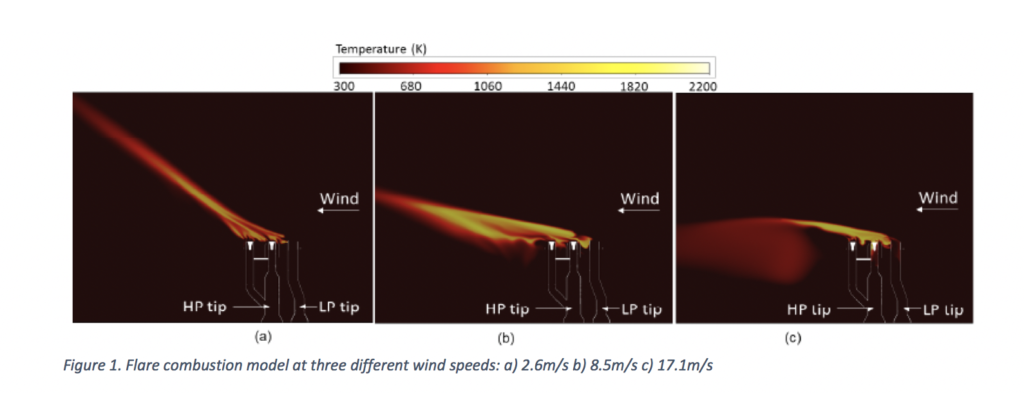

CFD modelling was commissioned to assess the Combustion Efficiency (CE)It is the percentage conversion of the hydrocarbon components entering the flare combuston zone to their end products of combustion i.e. CO2, and H 2 O. If following combustion there… Learn more… and the methane Destruction & Removal Efficiencies (DRE) at different wind conditions in an offshore production facility. The 3D model of the multi-tip sonic nozzle tip was developed and then the flare combustion was modelled at different wind speeds to determine the effect of cross winds on both CE and DRE. The work can determine if safety concerns could arise (such as internal combustion) as well as operational issues such as the flame stabilizing on the windshield which can result in damage to the tip.

Key findings:

Cross winds may lead to recutions in combusiton efficiency and destruction efficiency. Each facility shall have its own unique weather patterns which need to be considered during flare specification and operation. Insights into the effects of crosswinds come from both empirical studies and models.