Regular inspection of flare tips (or burners) is recommended to ensure their safe and efficient operation and can be a regulatory requirement in some locations.

Inspection can be used to check the mechanical integrity of the flare tip and its associated ancillaries like flare pilots and ignition system. Flare inspection can also be used to check the functionality of the flare tip, pilots and ignition system. Flares can be inspected when they are in operation and also when they are shutdown. Inspections can be performed manually or remotely with the use of drones, helicopters or cameras.

How it Works – Remote Inspection

Remote inspections can be completed with the flare in or out of operation. Visual inspections can be carried out from a safe distance using a telescope or cameras with zoom. Visual inspections can also be carried out using drones with cameras or from helicopters equipped with cameras. Thermal imaging cameras can be used to detect hot spots and leaks.

Inspection Guidance

Some suggested areas for inspection are;

Advantages

Inspections can be carried out frequently without requiring plant shutdowns

No requirement to enter flare restricted area or to work at height

The deterioration of defects can be monitored over time

Detailed photographs and video recordings of equipment can be made. In some cases, video can be livestreamed to experts in another location for immediate assessment

The operation of flare pilots can be checked, often using a thermal camera

Burning inside the flare tip (burnback) can be detected and the flare purge rate adjusted as required

Defective equipment can be identified, and spares purchased ready for installation at the next opportunity

Limitations

Inspections usually require good weather conditions to ensure the flare can be seen and photographed clearly

No physical checks of equipment can be made and no repairs to damaged equipment undertaken

The use of drones can be restricted by local Authorities or Regulators

The use of helicopters is often subject to approval and control by local aviation authorities particularly in onshore locations

Helicopter access can be restricted in some areas to avoid the exhaust plume and flare flames

Case study

Drone Inspection of Offshore Flare Tip

An inspection of a combined high pressure and low pressure flare tip and associated ancillaries was performed for an offshore facilityAn oil or gas production or processing facility that is designed to operate in water. The size, function and designs vary and includes, but is not limited to, jacketed structures… Learn more… which processes oil and gas from subsea wells. The inspection was carried out with the flares in operation using a drone mounted camera system.

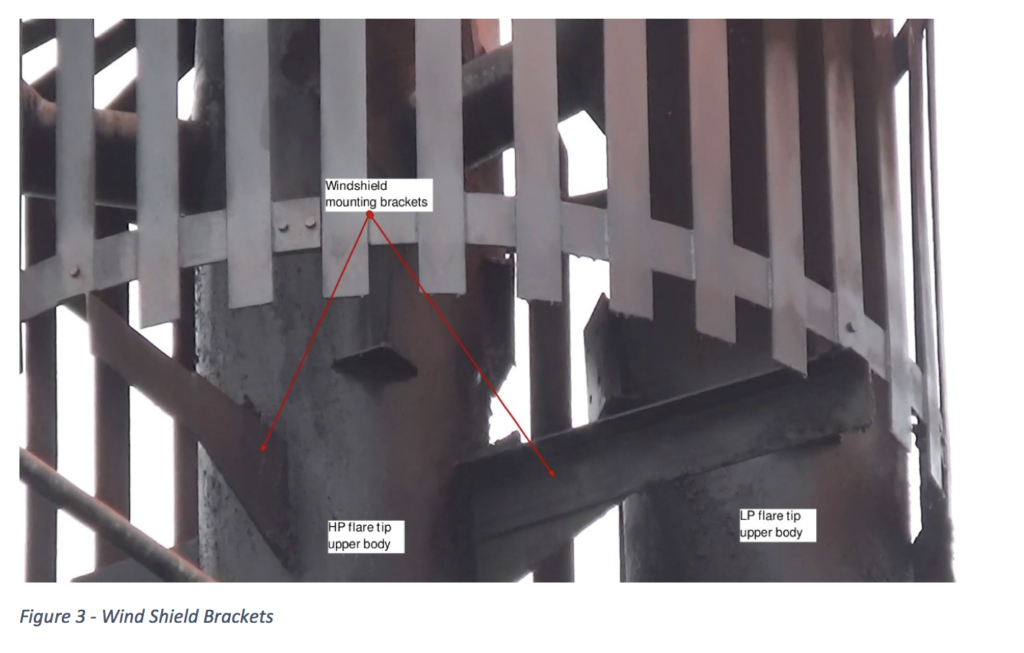

The inspection was able to show that the main tip was in relatively good condition with no deformation of the tips or damaged welds. The wind shield was showing a small amount of distortion.

The wind shield mounting brackets were in good condition.

The main flare tip flanges were in reasonable condition with all bolts present. There was also some evidence of contamination of the flare caused by liquid carry over.

These flares have no pilots and are ignited by a ballistic ignition system. The components of the system were checked and found to be in good condition.

Regular inspection of the flare is essential to maintaining safe and reliable operations. A range of techniues are now available to allow inspection to be carried out whilst the flare remains operational which reduces the risk of poor combustion efficiency