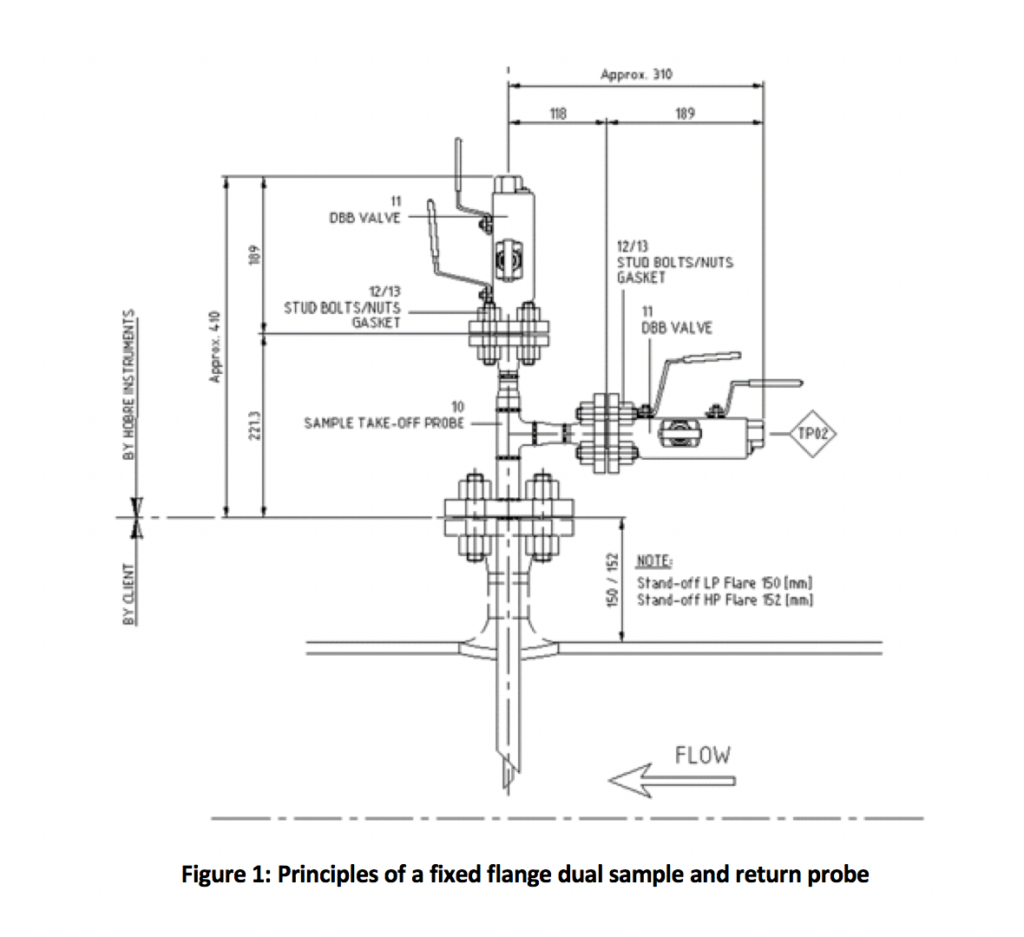

Fixed flange dual sample and return probes are permanently installed on a flare system line usually on the top of a horizontal pipe or in the flare knock out drum. They are flanged connected, isolated with a DB&B valve, and can only be removed for maintenance during a flare system shutdown.

How it Works

Fixed flange probes protrude through a double block & bleed valve isolation arrangement to extract a sample of the flowing gas nominally from the centre third of the pipeline.

The added benefit of a fixed flange dual sample and return probe, is that instead of having to install an additional nozzle to return the sample to process, this can be returned through the outer annulus of this probe.

Fixed flange probes inserted into a process line, such as a flare line, must undergo wake frequency calculations to will not fail during maximum flaring conditions.

With a flare line, the fixed flange probe must protrude into the flare line by a minimum of 25.4mm (1”) to extract the sample and the maximum intrusion depth is dependent on the wake frequency calculation acceptable criteria.

Fixed flange dual sample and return probes can only be inspected or have maintenance conducted during a flare system shutdown.

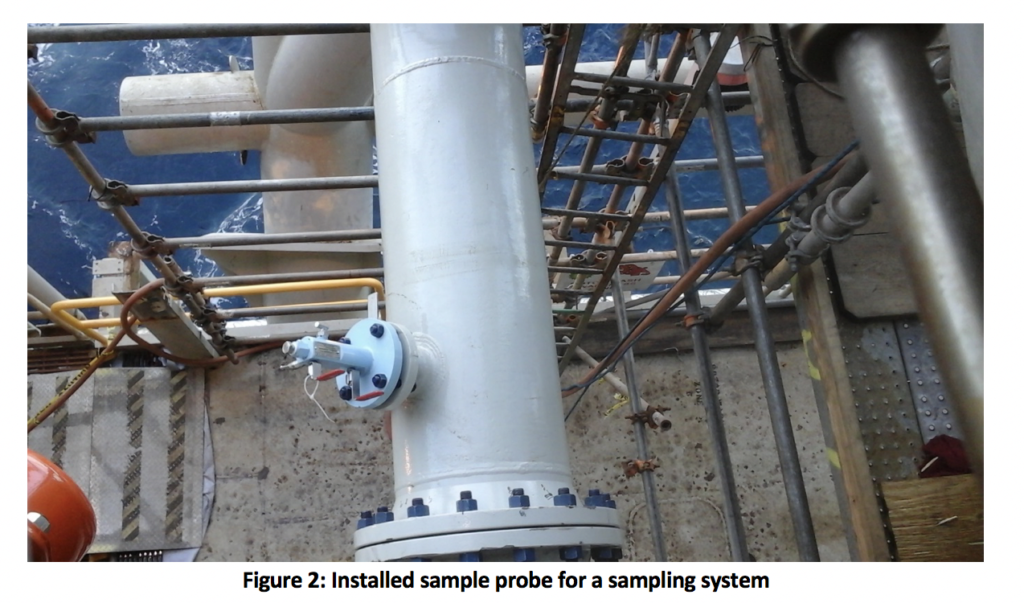

Fixed flange dual sample and return probes are installed on multiple systems globally to either take samples for laboratory analysis or analysis by on-line analyser systems.

Advantages

Sample can be returned to process through same location

Low installation costs

Low maintenance costs

Limitations

Can only be installed during a flare system shutdown

Can only be inspected and/or maintained during a flare system shutdown

Must be designed to handle the very high velocities in flare system pipework

Case study

No case study available at this time.

Taking an effective sample is based on the type of probe to be used in the application required.