LiDAR or Light Detection and Ranging is an 3D imaging technology based on laser beams. It is also referred as “laser scanning” or “3D scanning” The technology uses eye-safe laser beams to create a 3D representation of the surveyed environment including targeted gas plumes.

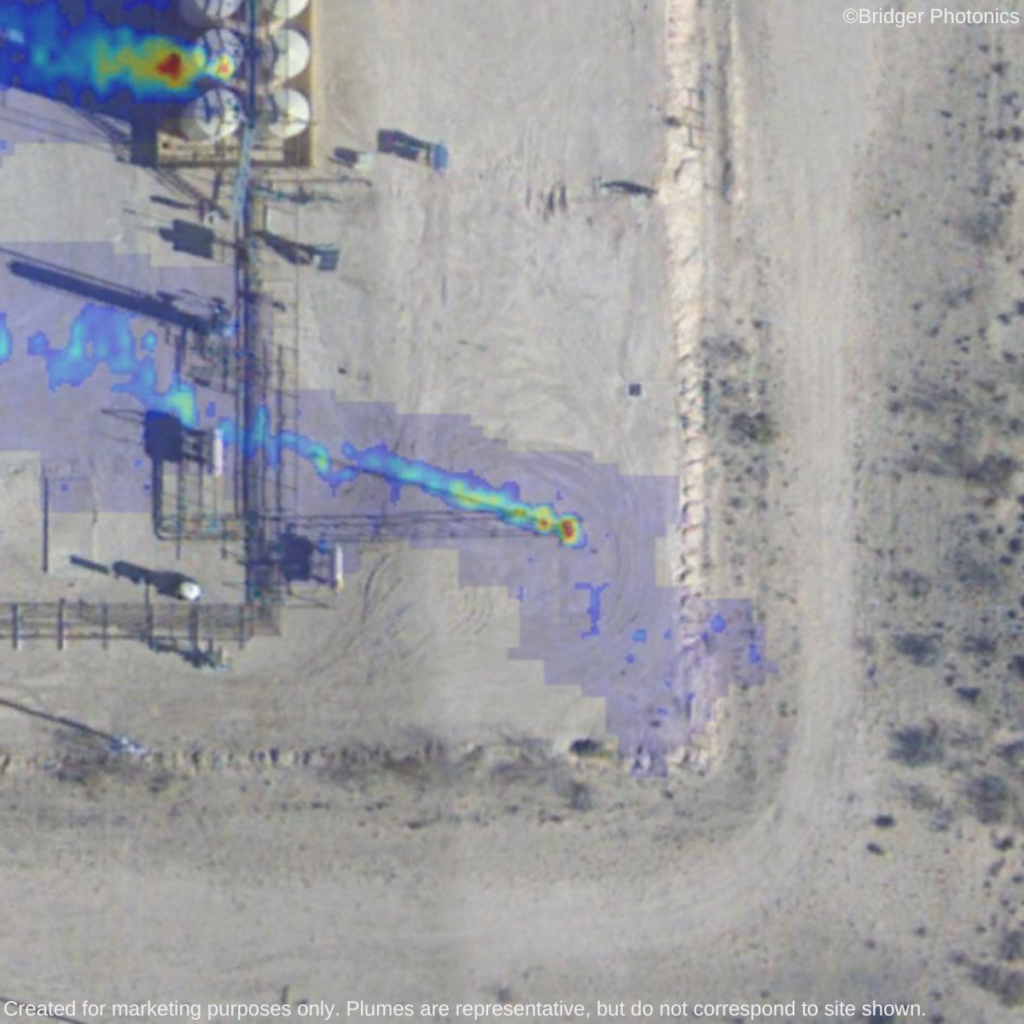

Mounted on a drone or aircraft, the LiDARLidar is a method for determining ranges (variable distance) by targeting an object with a laser and measuring the time for the reflected light to return to the receiver. LiDAR… Learn more… sensor continuously scans a site with a laser of a specific wavelength that can only be absorbed by a target gas, in this case, methane. The sensor measures the time taken for the light pulse to bounce back from the target. The LiDAR unit takes thousands of data points per second to generate geo-registered gas plume imagery which, when combined with advanced analytics and other meteorological data, creates color-coded maps of precise methane leak locations and emissions rates.

Advantages

Ability to measurement from a safe distance from a site, especially when used from a helicopter or fixed wing aircraft.

Can do multiple sites per day - up to 250 sites a day (typically 100-150) when mounted on aircraft.

Potentially very sensitive methane detection – e.g., 3 kg/hr with greater than 90% probability of detection in typical conditions for production site using aircraft-mounted unit.

Can catch very high percentage of a site’s methane emissions, depending on flight altitude.

Ability to identify emissions at the equipment level resulting in actionable data for follow up and timely repair.

Potentially reduce ground survey.

Easy to understand visual imaginary.

Capable of measuring emissions inventories throughout the entire natural gas supply chain.

Limitations

Scanning days and times limited by safe conditions [visual flight rules (VFR)] and by requirement for ground wind speed of <11 m/s

Consideration of windspeed is required to ensure accurate methane quantification.

Difficulty measuring sources near snow or water background, thus not applicable for offshore platforms.

Ability to detect and quantify methane slip from hot exhaust stacks such as compressor engines, turbines or inefficient flares not yet demonstrated.

Where the Methane Is – Insights from Novel Airborne LiDAR Measurements Combined with Ground Survey Data David R. Tyner and Matthew R. Johnson* : Environ. Sci. Technol. 2021, 55, 9773−9783

Summary courtsey of Bridger Photonics

Key Takeaways from EERL’s “Where the Methane Is” Study | Bridger Photonics

The “Where the Methane Is,” study was conducted with the goal of deriving a new measurement-based methane inventory for oil and gas facilities in British Columbia, Canada. Carleton University’s Matthew Johnson and David R. Tyner of The Energy Emissions Research Lab conducted the study utilizing onsite OGI survey data combined with aerial scan data from Gas Mapping LiDAR™. Findings from their work provide beneficial new data for the oil and gas industry.

The following are a few of the highlights:

To better understand the primary sources of methane leaks, the study combined data from onsite optical gas imaging (OGI) surveys and pneumatic device counts with airborne measurements by Gas Mapping LiDAR. The results revealed that four sources were responsible for 72% of the emissions: production tanks (24%), pneumatic devices (20%), reciprocating compressors (15%), and unlit flares (13%).

Why It’s Important: By having a clearer understanding of the frequency, distribution, and magnitude of various source types driving upstream oil and gas emissions, policy and regulations can focus on these sources to set meaningful reduction targets. Measurements versus estimates also help operators accurately prioritize equipment replacement and repair schedules based on the most common and significant sources of emissions.

Aerial scans with Gas Mapping LiDAR found significantly larger and many times greater total emissions than the OGI survey. When analyzed in conjunction with equipment count data, the study suggests methane emissions are 1.6 to 2.2 times greater than current inventory estimates.

Why It’s Important: Canada’s current policies and regulations rely on inventory estimates based on OGI survey data, which the study states could run the risk of missing a significant portion of total emissions from tanks and unlit flares. Emerging policies and regulations should be based on meaningful emissions reduction goals using accurate data as a foundation. To amplify this point, CBC News dove deeper into how this could affect the Canadian government’s multi-million dollar plan to reduce methane emissions.

When compared with the ground-based OGI surveys, Bridger’s aerial LiDAR detected significantly more aggregate emissions on the same set of facilities – as much as 18 times more methane detected – but from far fewer emissions sources. Aerial LiDAR scan data provided high-resolution, geo-located aerial imagery, facility schematics, and equipment counts that enabled equipment-level emission attribution.

Why It’s Important: The results showed that OGI surveys underestimated fugitive emission and abnormal venting that could impact the accuracy of inventories and could miss a significant portion of emissions. Aerial LiDAR found more emissions from fewer sources than the OGI cameras and consistently attributed emissions to source types. By using the results of an aerial Gas Mapping LiDAR scan, operators can improve emissions inventory accuracy and make meaningful impact on emissions reduction with fewer repairs, ensuring that ground crews fix the most important leaks first.

The discrepancy in undercounted emissions is attributed to larger (i.e., > 0.6 kg/hr) emissions that were detected by Gas Mapping LiDAR, but that were statistically less likely to be found by ground crews with OGI cameras. The leaks detected by aerial LiDAR tended to be larger than what OGI cameras found. The study notes that this could explain the discrepancies in current inventory estimates versus the results of the study.

Why It’s Important: The benefits of aerial methane detection are increased efficiency for site scans, as well as the aerial versus OGI’s ground-level viewpoint to equipment sources and emissions. Gas Mapping LiDAR’s capabilities help identify emissions in places that are not captured by OGI cameras, suggesting that relying solely on OGI cameras is not optimal to establish accurate inventories, base policy and regulations upon, nor achieve quantifiable emissions reduction goals.

The work being done by the Energy and Emissions Research Laboratory is crucial to better understanding methane emissions at aggregate and source levels. This important study helps identify ongoing improvements that can be made and the technology that can help the oil and gas industry make meaningful improvements.

LiDAR or Light Detection and Ranging is an 3D imaging technology based on laser beams. It is also referred as “laser scanning” or “3D scanning” The technology uses eye-safe laser beams to create a 3D representation of the surveyed environment including targeted gas plumes