The formation of soot and smoke by a flare can provide qualitative information that there may be a problem with combustion efficiency.

Whilst not directly correlated with methane emissions, the formation of soot may indicate to the operator that a flare is not performing properly or that conditions have changed.

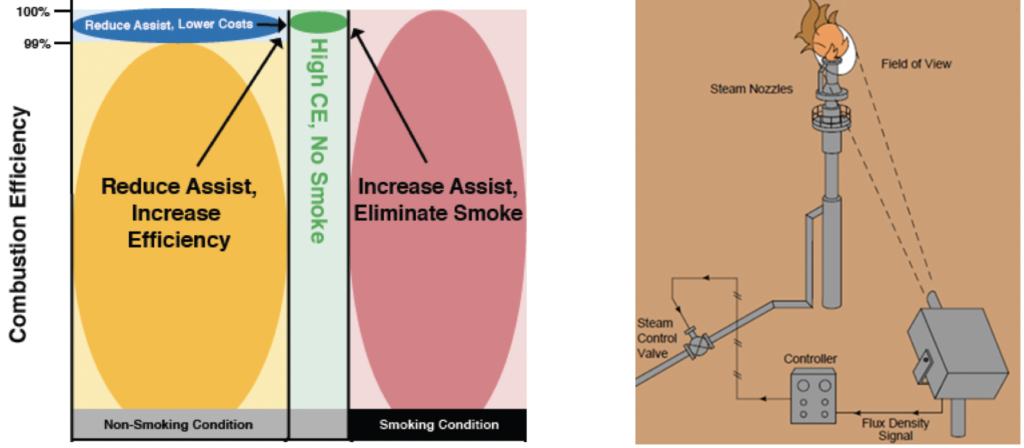

To comply with environmental regulations in some countries it is essential to have a good flare monitoring and control protocol and to avoid the formation of undesirable soot and smoke. However, excessive injection of air or steam may reduce combustion efficiency, resulting in unburnt hydrocarbons released to the atmosphere.

A large number of flares operate with the assistance of supplemental high-velocity air or steam to prevent the formation of soot or smoke. Flare monitoring has traditionally been performed on a manual basis, with a plant operator visually monitoring the flare and recording incidents like the occurrence of black smoke. This procedure is both inefficient and prone to errors. Human attention span is limited, and operators can get distracted by other work. This can result in missing an incident like black smoke, excessive steam when monitoring the flare for an extended period, and can lead to non-compliance or inefficient flaring.

To avoid these problems, it is important to monitoring smoke generation and to implement control of assist media flow to ensure proper combustion with high destruction efficiency independent of the waste gas composition and flow.

Soot monitoring includes the use of optical cameras with infraredA wavelength just greater than that of the red end of the visible light spectrum but less than that of microwaves. Infrared radiationhas a wavelength from about 800nm to 1… Learn more… (IR) technology to measure in the infrared spectrum.

Advantages

Avoid smoke or black carbon generation

Help to have proper combustion with high destruction efficiency

It reduces utility consumption

It prolongs equipment life

Limitations

Soot formation does not directly correlate to methane emissions. Excessive use of supplement gases may suppress soot but increase methane release

It doesn’t measure the combustion efficiency in the flare

Case study

Case Study: Sky Losa

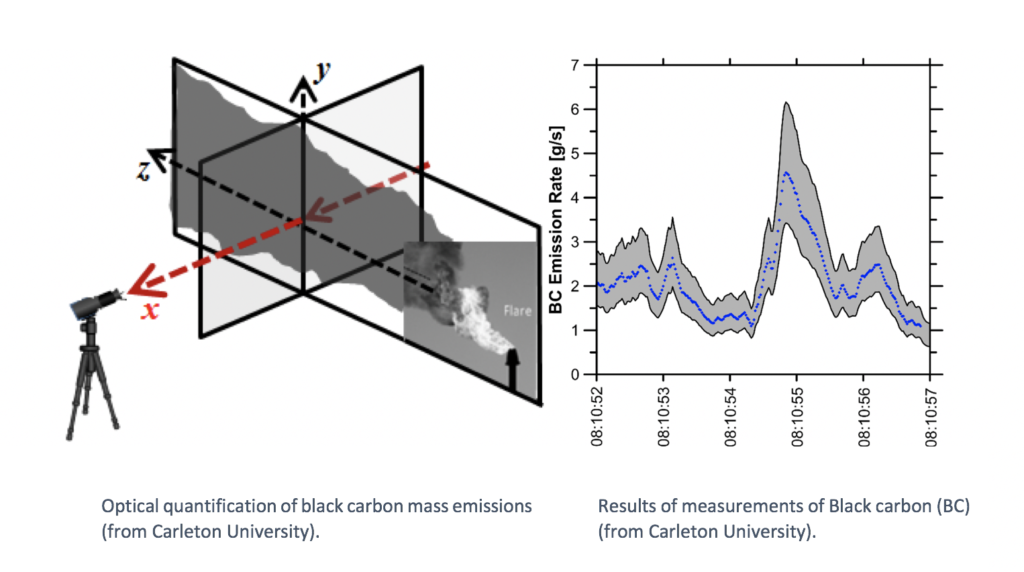

The Energy & Emissions Research Lab. From the Carleton University, Ottawa (Canada) is quantifying the Black Carbon yield (mass black carbon per mass of fuel) from an atmospheric plume of a flare.

For in-situ, optical quantification of black carbon mass emissions, Sky-LOSA = Line-Of-Sight Attenuation of skylight is used. The methodology is based in Rayleigh-Debye-Gans theory for Polydisperse Fractal Aggregates (RDG-PFA). For the black carbon measurements, it is required:

Secondary data - such as the appearance or increase of soot may be used to infer that the performance of a flare has changed. Whilst this is not a measure of methane itself it may act as an indicator for further investigation.