An ultrasonic flow meterUltrasonic Measurement uses sound waves to interrogate the fluid or object and determine various key properties. The sound waves are typically sent and received by a piezo electric transducer which… Learn more… measures the velocity of a fluid with ultrasound to calculate volumetric flow.

Using ultrasonic transducers, the flow meter can measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow or by measuring the frequency shift from the Doppler effect.

Ultrasonic flow meters are affected by the acoustic properties of the fluid and can be impacted by temperature, density, viscosity, and suspended particulates depending on the exact flow meter.

They vary greatly in purchase price but are often inexpensive to operate and maintain because they do not use moving parts, unlike mechanical flow meters.

How it Works

Ultrasonic flow meters measure the average velocity along the path of an emitted beam of ultrasound, by averaging the difference in measured transit time between the pulses of ultrasound propagating into and against the direction of the flow.

IMAGE TO FOLLOW

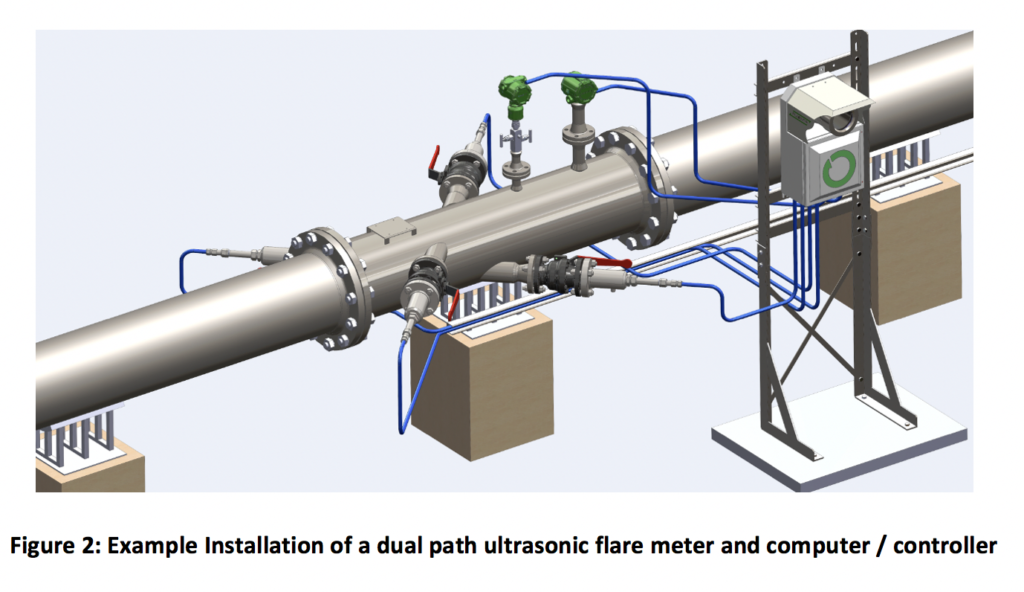

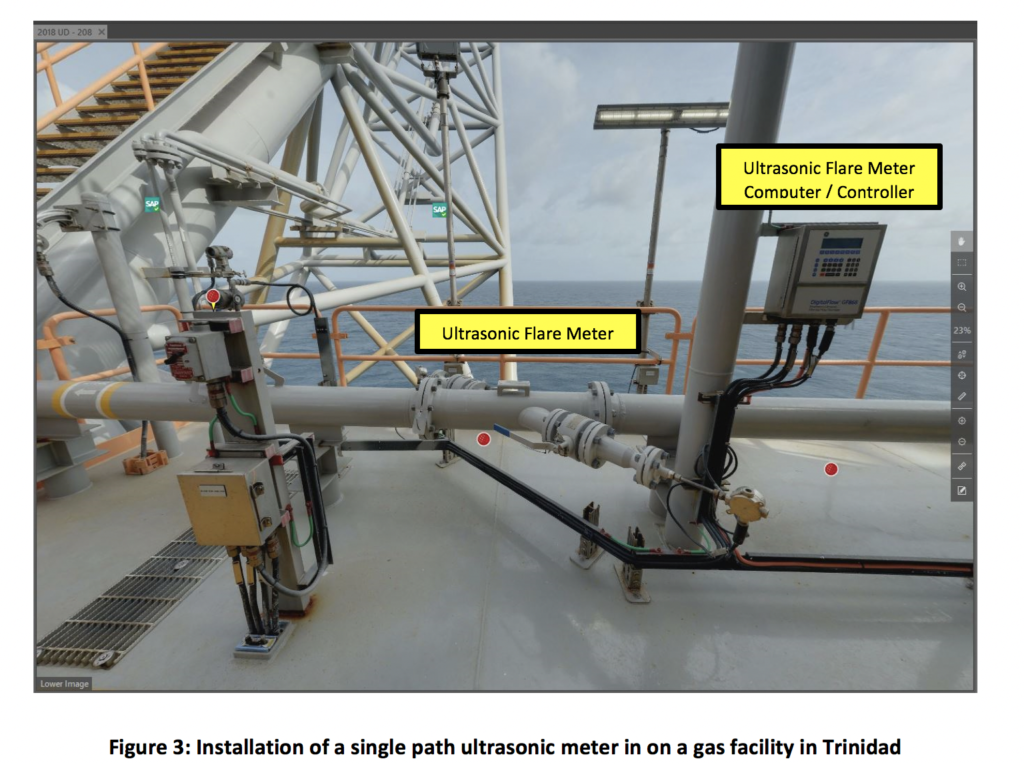

Ultrasonic flow meters can either be single or dual path dependent on installation requirements and operating conditions.

Advantages

No restriction to flow in the flare system

Operates reliably even with an unsteady flow, pulsating pressure, varying composition and temperature, and harsh environments

Large velocity and turndown range: 0.1 to 400 ft/sec (0.03 to 120 m/s), high turndown ratio of 4000:1

Available in large line sizes up to 120 in (3 m) in diameter

Predictive maintenance capability by utilising instrument diagnostics to check meter’s health and performance

Primary measurement independent of pressure and temperature

No moving parts or orifices, nothing to clog or wear out

No regular maintenance required (flow measurement is independent of gas properties)

Limitations

Flow meter requires straight lengths of pipe upstream and downstream when being installed

Swirl can have an effect on the ultrasonic flare meter measurement, if the system is not designed to comply with the operating conditions of the facility

Case study

No case study available at this time.

Ultrasonic Measurement uses sound waves to interrogate the fluid or object and determine various key properties. The sound waves are typically sent and received by a piezo electric transducer which converts electric signals to pressure waves and vice versa. In most flowmeters, the ultrasonic signals are used to precisely measure downstream and upstream transit times in a pipe. Transit time is then converted to a flow rate. The transit time also allows accurate determination of the gas sound speed, which in turn enables further properties to be calculated such as molecular weight.