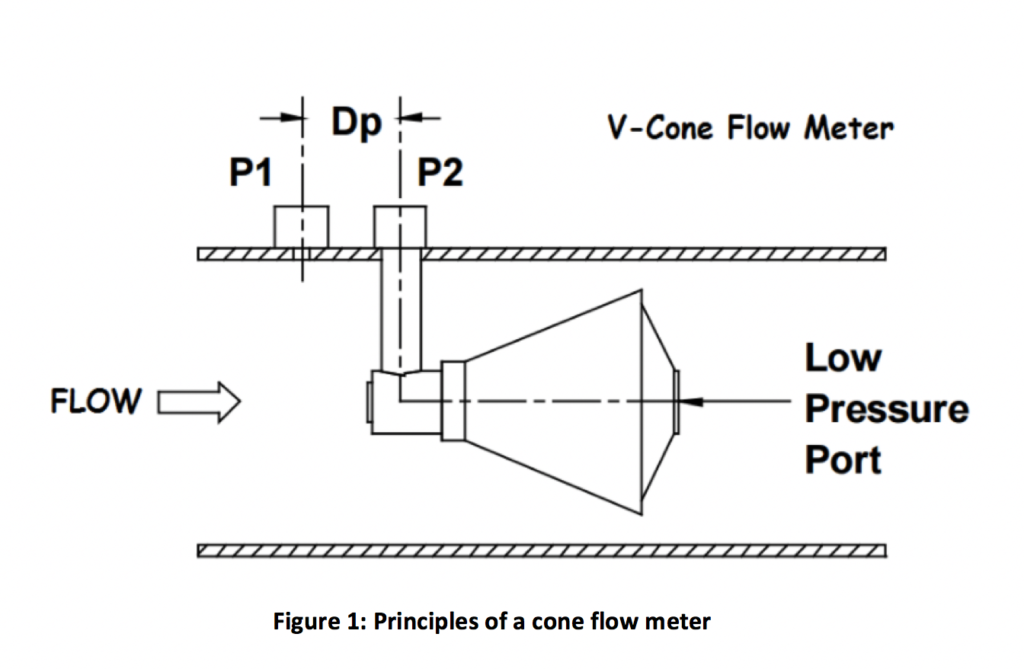

A Cone or V-Cone flow meter is a differential pressure device.

An obstruction in the pipe (i.e., a reduction in the cross-sectional area available to the flow) causes an increase in the velocity of the flowing fluid and a corresponding reduction in its pressure.

How it Works

As the fluid approaches the V-Cone flow meter, it will have a pressure of P1.

As the fluid flows past the constricted area of the V-Cone its velocity increases and its pressure drops to P2. Both P1 and P2 are measured at the V-Cone flow meter’s taps using a differential pressure transducer.

The differential pressure (Dp) measured at the V-Cone flow meter will increase and decrease with the flow velocity.

Advantages

Well proven, simple, and robust metering principle

Lower sensitivity than orifice plates and venturi tubes to installation effects

Does not require significant lengths of straight pipe to be installed upstream

Limitations

Not suited for low flow velocities

V-cone presents a significant restriction to flow in the flare system

Results in a high permanent pressure drop

Limited turndown ratio, typically 4:1

Lack of design standards

Go Deeper

Case study

No case study available at this time.

Differential pressure meters work on the principle of calculating a flow rate based on the change in pressure between two measured points.