A methane sensor is flown in to the emissions plume of the flare. Without measuring carbon dioxide, carbon monoxide or soot the combustion efficiency or destruction efficiency of the flare is not measured directly. The emission rate can be calculated by applying dispersion models and the combustion efficiency calculated by comparison to metered flow rates.

The technology is common to techniques also used for other methane measurement activities – such as leak detection and repair and can therefore be combined with these kinds of operations.

Several methane sensorsSensors are devices that measure physical properties such as methane concentration, temperature, or radiance. For measuring flare efficiency the sensor must be capable of measuring methane and in some cases… Learn more… are now commercially available. In the case study, an in-situ methane sensor based on tuneable diode laser absorption spectrometer TDLAS technology provides direct and real-time measurement of methane concentrations. TDLAS technology is deployed on small unmanned aerial systems (UAS) and coupled with wind speed is used to accurately detect, localise and quantify methane emission sources. The method is used to quantitatively assess all methane emission sources and can be used to determine combustion efficiency of energy-sector combustion equipment including flares. Calculation of destruction efficiency requires access to accurate flow data. Technology of this kind has the potential to work for flares of all sizes and locations, including offshore and be integrated into wider methane measurement activities including LDAR. Measurement is based upon a tuneable diode laser absorption spectrometer, measuring absorption of mid-wave infraredA wavelength just greater than that of the red end of the visible light spectrum but less than that of microwaves. Infrared radiationhas a wavelength from about 800nm to 1… Learn more… light to obtain the relative concentrations of CH4. The sensor is placed in either an open or closed cavity to enable in-situ sampling of the local methane concentration.

A mass balance is performed by flying the aircraft in a raster pattern downwind of the flare or orbiting the flare. Using locally measured wind speed and direction the Methane emission rate is performed. The operator provides gas composition to flare, which is used to derive Combustion Efficiency and Destruction Efficiency.

Image courtesy of SeekOps

Advantages

Field-proven in both onshore and offshore environments

Exploits automation capabilities for repeat surveys to determine temporal evolution of efficiency

Full three-dimensional coverage of flare plume

Survey can be made a few meters from flare to a few hundred due to high sensor sensitivity (ppb)

Can be run night and day and in cloudy and light rain conditions

Can survey emissions for all equipment groups as well as asset level cumulative emissions

Limitations

Needs to be downwind of, or have ability to circumnavigate, the emission source

Some limitations in severe weather conditions (e.g. heavy fog, heavy rain)

Trained UAS Operator for set-up

Specific to CE/DE - Need gas composition and flow-meter readings for CE and DE, because of inability to measure CO or CO2

Permits required to fly close to flares

Drones have a finite battery duration that determines the maximum area that can be flown when measuring upwind and downwind methane concentrations.

Case study

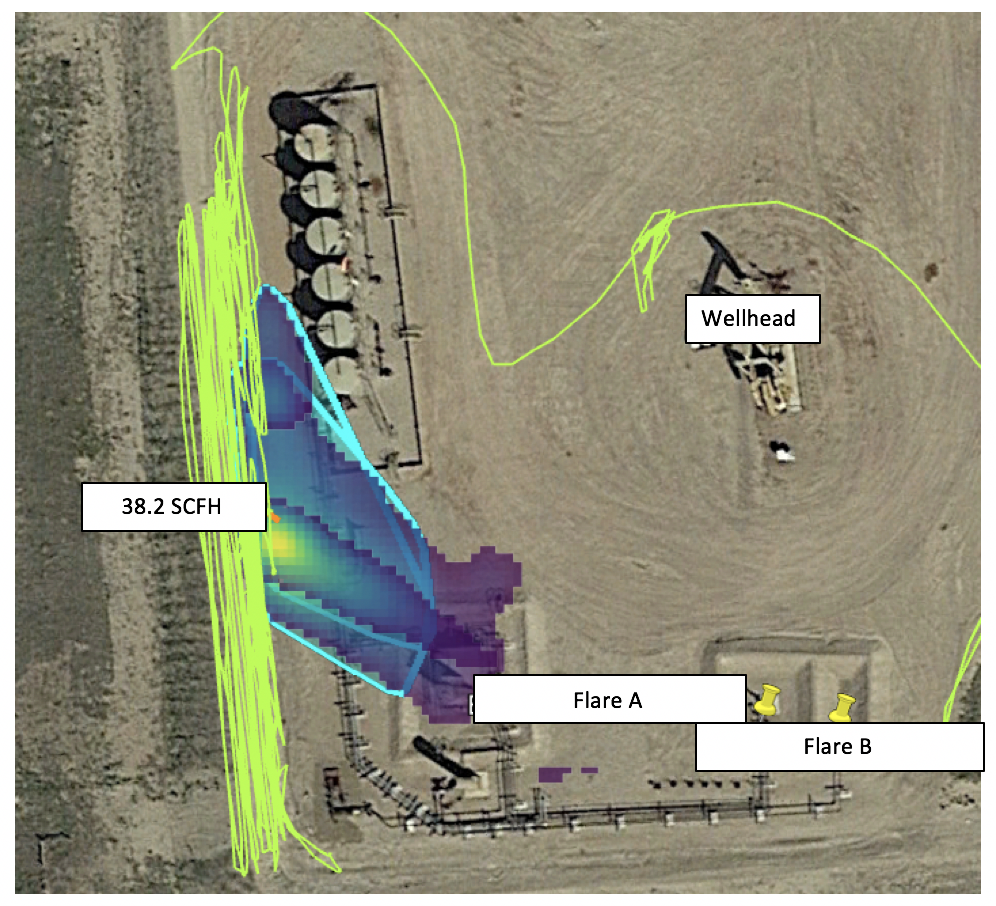

Flight path of a drone measuring flare emissions from an onshore well-pad.

The example below highlights UAS flight paths and associated methane concentrations for a Rod-Lift Production Pad with associated flaring showing how the methane plume from the flare can be differentiated from other potential sources of the site and converted in to a emission rate.

Sensors are devices that measure physical properties such as methane concentration, temperature, or radiance. For measuring flare efficiency the sensor must be capable of measuring methane and in some cases other combustion products. The sensor has to be manouvered in to a location where it intersects with the flare plume - either through the use of drone technology or aircraft. Where only methane is being measured, additional data on flare volumes is required to derive combusiton effificiency estimates.