Summary

A large number of tools are available to simulate various aspects of flare systems.

The capabilities of these software tools range from determining the release rate of relief valves and emergency depressuring systems to modelling the hydraulics of the flare system pipework to determining the thermal radiation, noise and final dispersion from vents or lit flares.

The different software tools have strengths in specific areas and often multiple tools are required if it is desired to simulate all aspects of a flare system. The main purpose of flare simulation is usually to ensure that the flare and relief systems can be designed and operated safely. Although they can provide information which is useful when examining the release of methane to the atmosphere, this is not their primary focus and they cannot be used to predict flare combustion efficiencies, for example.

Flare and Vent System Inflows

Flare and vent systems must be designed to receive fluids from a number of different sources. These can flow intermittently, for example from relief valves or emergency depressurisation systems, or continuously, for example from vessel vents or the flare system purge.

Simulation software can be used to record all potential sources of inflow to the flare system and, since it is unlikely that all sources will be flowing simultaneously, to record different scenarios which might be expected to occur in the operating life of the facility. Certain information about each source can be documented including its likely flowrate, temperature and composition. The parameters of some sources will vary with time, and this variation can also be recorded.

This information is essential when designing a flare system and can also be useful in determining the likely quantity of material sent to the flare system if a relief valve has opened.

Flare and Vent System Hydraulics

The flare or vent system can be required to handle fluids released from a range of sources and it is important for the flare designer to understand the impact of these fluids on the flare system. Specialised software can be used to determine the combined flowrates, pressure and temperatures of the fluids flowing in the flare system depending on the sources released into it.

Fluids flowing in the flare system can also undergo changes in state (gas, liquid, solid) depending on their temperature and pressure. Fluid temperature and pressure can be influenced by the original sources’ conditions, the flare system geometry, and the ambient temperature outside of the flare pipework. Since most flare and vent systems include a vessel to capture any liquids before vapour is sent to the flare burner or point of discharge, a flare system simulation can be used to predict what the composition of the vapours finally discharged will be.

Other uses for a hydraulic model are to predict the likely conditions and composition of fluids passing through any flare or vent gas metering system and to predict the velocity of fluids existing the flare tip or vent stack.

Flare and Vent System Noise, Radiation and Dispersion

One the fluids in the flare or vent system reach the flare tip or vent stack exit they will be combusted or released to the atmosphere un-combusted. The size, shape and direction of any flame produced will depend on the rate of release of the material, its density and the wind speed and direction. These can be predicted using specialist flare modelling software.

When material is burnt in a flare tip, combustion products are produced as well as heat radiation and noise. Software packages can be used to predict the level of radiation and noise at various positions around the point of release. Software can also be used to predict the dispersion of combustion products or, if discharged from a vent, the dispersion of unburnt products. This is particularly useful as it important to ensure that toxic or flammable components are disposed of safely.

Sometimes vendors provide their own estimates of the combustion efficiency of their tip and this can be used, in conjunction with the gas release rate and compositions to estimate the amount of unburnt methane and other hydrocarbons emitted by a flare. Vendors can also provide their own predictions for flare radiation and noise which may have been determined through large scale testing and can be incorporated into the flare simulation models.

Advantages

Flare simulation software can be used to document potential release rates to the flare or vent system.

Simulation software can predict the composition, physical properties, and conditions of fluids at any point in the flare system.

Software can be used to predict flare radiation and noise and the dispersion of combusted and un-combusted products as they are released to the atmosphere.

Limitations

Flare simulation software cannot reliably predict the combustion efficiency of different flare burners.

Multiple software tools are required to simulate all aspects of flare and vent systems.

Go Deeper

Case study

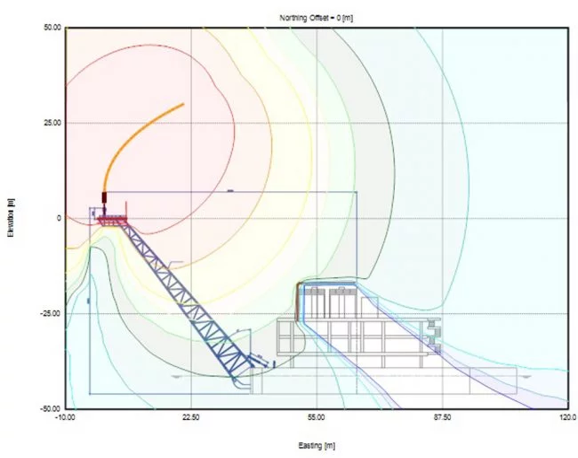

1)It was desired to debottleneck an existing offshore oil and gas production platform to allow it to produce oil and gas from a nearby undeveloped reservoir.

2)The platform included a permanently lit elevated flare for disposal of routine and emergency gas releases.

3)The new oil and gas that the platform wanted to produce would increase the amount of gas sent to the flare in some emergency situations.

4)Specialist software was used to calculate levels of heat radiation from the flare for the offshore installation. It was found that the radiation received by certain locations on the platform would exceed the level which was safe for the platform workers.

5)One solution to the problem would have been to extend the length of the flare structure, this would move the flare tip away from the platform and reduce the amount of heat radiation it would receive. However, this would costly and would require the platform to be shutdown for a long time to allow the modifications to be made.

6)Instead, specialist software was used to determine the optimum location and construction of radiation heatshields. These heatshields or heat barriers would protect key equipment and personnel from excessive levels of heat radiation.

7)The heatshields were installed which allowed the platform flare system capacity to be increased and the debottlenecking project to proceed.

The efficiency of combustion can be calcualted based upon the flare gas composition, volumes and data on the flare design from which exit velocities and mixing can be estiamted. These calcualtions can either be done by the operator directly or obtained from pre-built simualtion software. Recent advances incomputing have supported development of predictive systems providing real-time feedback on calculated values. In all cases, the quality of calculations is dictated by the quality of data that is available on flare volumes, compsition and flare design.