Summary

A flare can only achieve its objective of safe and efficient disposal if the exiting gases are ignited, and the ignition is sustained. Ignition can be sustained through the use of a flare pilot system which includes the flare pilot, the ignitor, and a pilot flame monitor.

When the flare is in service the flare tip or burner and its pilots are remote, inaccessible, and exposed to external influences. The pilot must be capable of operating for long periods of time without adjustment or maintenance.

How it Works

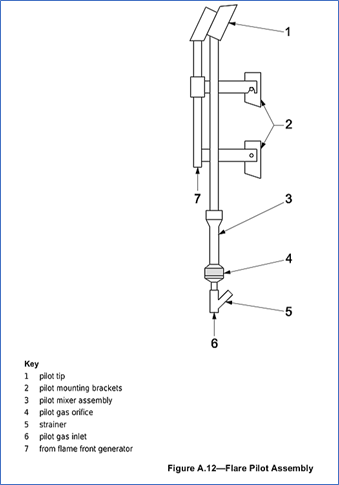

The pilot usually consists of a pilot tip, a windshield, a venturi mixer and a metering orifice. Most flare manufacturers use a premixed pilot where flammable gas and air are mixed together before combustion. Premix pilots offer greater stability over raw gas burners.

The pilots are placed close to the outlet of the main flare burner. The number of pilots required depends on the size of the main flare burner.

Pilots must be able to provide sufficient energy to initiate burning of the waste products as they exit the flare tip. The amount of energy required depends on a range of factors including the composition of the gas being flared, the design of the flare burner and the atmospheric conditions the flare must operate in.

Flare pilots are often designed to meet international standard API 537 which requires them to remain lit under various combinations of high wind and rainfall.

Advantages

Robust, well proven technology

No moving parts

Can be used with a wide range of ignition and flame detection technologies.

Pilots can be designed to light and remain burning even when main burner flare gas is not flowing or is not flammable

Can be designed to be removable for maintenance when main flare is in operation

Limitations

Pilots can be exposed to corrosive gases or combustion products and should be made from corrosion resistant materials.

Pilots can be engulfed by the main flare flame and suffer overheating and thermal damage.

Pilot fuel gas must be filtered to remove solids and avoid blocking the pilot orifice.

Unless designed to be retractable, pilots cannot be maintained unless the main flare is shut down.

Pilot burners emit some CO2 and unburnt methane as part of the combustion process.

Case study

Image of pilot in operation

Ensuring that a flare ignites when required is critical to safety. In addition, periods of unlit venting may increase the impact of the flare as a source of greenhouse gases as methane has a higher global warming potential that carbon dioxide. Where a flare is used periodically there are a range of technology solutions to ensure ignition on demand.