Image courtesy of Zeeco, Inc.® – all rights reserved.

Sonic tips are designed to discharge the flare gas at sonic velocities. The most conventional technology is the multi-arm design, with fixed or variable exit areas.

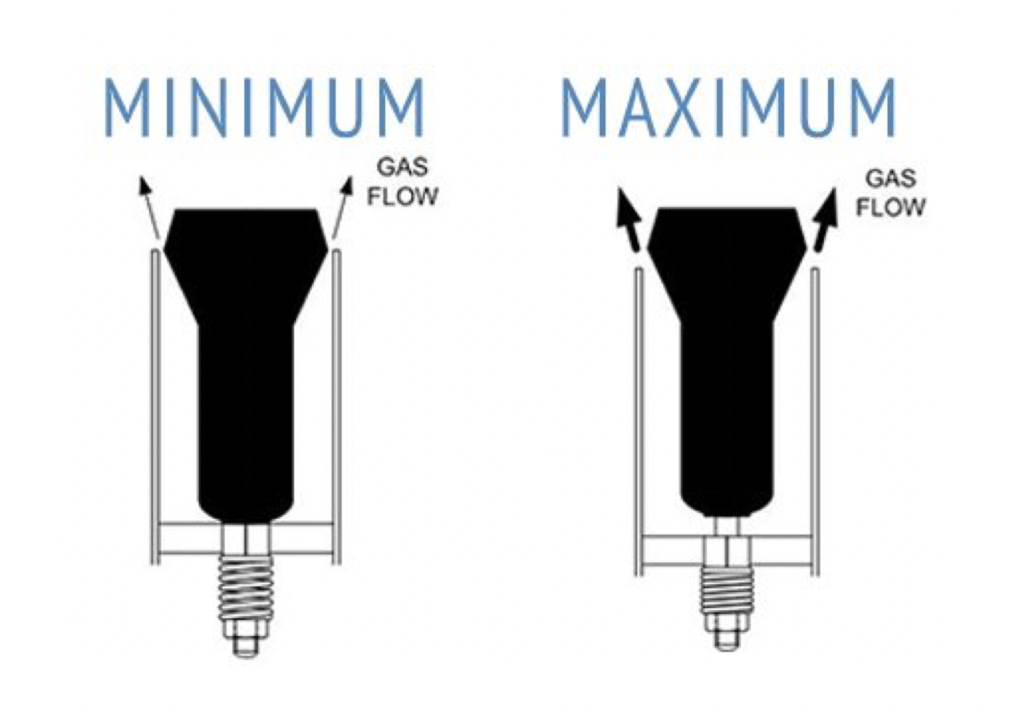

Variable exit tips allow greater flexibility in dictating the velocity of gas, and therefore mixing with air for low emission combustion. However, additional moving parts adds complexity to the flare design.

Advantages

High combustion efficiency at high flowrates resulting in reduced smoke formation

Sonic discharge over the entire operating range – high turndown capacity

Improved performance at low flow rates – better mixing with combustion air, increased combustion efficiency, smokeless operation

Low purge ratesThe flowrate of flare purge gas Learn more... – the exit area is almost completely closed at low flow rates; therefore, less purge gas is required to prevent air ingress in the flare tip, lowering emissions from purging

Limitations

Sonic tips with variable slots involve moving parts with an inner spring which can be challenging for inspection.

Go Deeper

Case study

Flares are a safety device and many designs require the flare to remain permanently lit. To ensure that there is no ingress of air into the system (which may lead to an explosion) a minimum amount of gas passing through the flare is required. This purge gas is part of safe and reliable operations. For flares that spend extended periods in this standby state the amount of gas consumed is a significant contributor to overall emissions including methane. This may be reduced in a range of flare designs.