Thermal mass flow meters, also known as thermal dispersion or immersible mass flow meters, are for the measurement of the total mass flow rate of a fluid, primarily gases, flowing through closed conduits.

How it Works

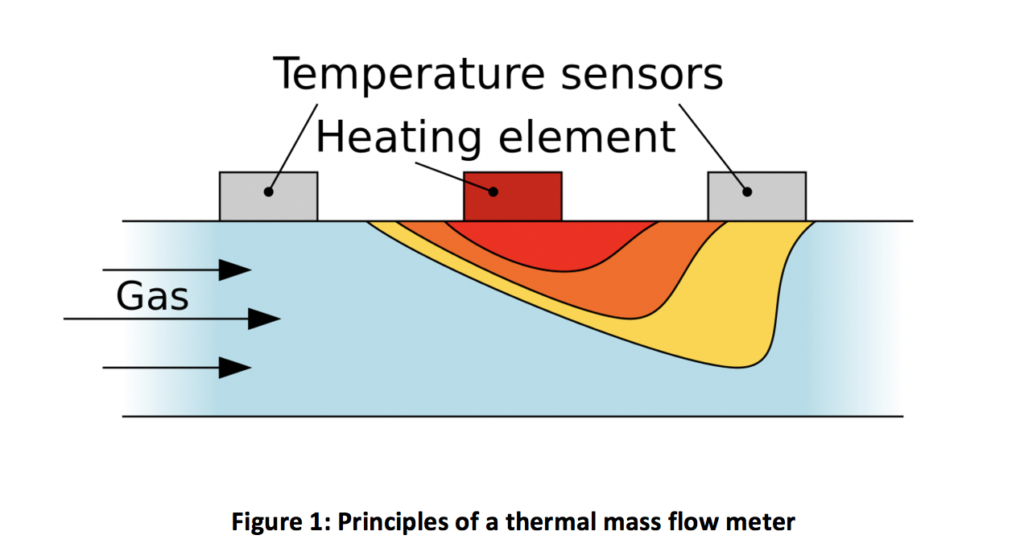

Thermal mass flow meters determine the flowing fluid mass flow rate by measuring the heat convected from a heated surface to the flowing fluid.

In the case of the thermal dispersion, or immersible, type of flow meter, the heat is transferred to the boundary layer of the fluid flowing over the heated surface.

In the case of the capillary-tube type, the heat is transferred to the bulk of the fluid flowing through a small, heated capillary tube.

The principles of operation of the two types are both thermal in nature but are substantially different that two separate international standards are required.

Additionally, their applications are much different. Thermal dispersion flow meters are commonly used for general industrial gas flow applications in pipes and ducts, whereas capillary types are primarily used for smaller flows of clean gases or liquids in tubes.

Advantages

Thermal flow meters have no moving parts, reducing maintenance and permitting the use in demanding application areas, including saturated gas

Thermal mass meters calculate mass flow rather than volumetric flow

Usually present no restriction to flow in the flare line

They do not require temperature or pressure correction

Low cost

Can be calibrated in situ

No requirements to be installed with upstream or downstream straight lengths of pipe

Limitations

Requires calibration on specific composition of gas being measured

Cannot tolerate liquids particularly water vapour

Presence of hydrogen will affect the accuracy

Turndown ratio up to 1000:1

Insertion type meters can be damaged by wake induced vibration at high gas velocities

Case study

No case study available at this time.

Thermal mass flow meters, also known as thermal dispersion or immersible mass flow meters, are for the measurement of the total mass flow rate of a fluid, primarily gases, flowing through closed conduits. The operation of thermal dispersion mass flow meters is attributed to L.V. King who, in 1914, published his famous King's Law revealing how a heated wire immersed in a fluid flow measures the mass velocity at a point in the flow. Industrial-grade thermal dispersion mass flow meters were introduced in the 1950’s and 1960’s.