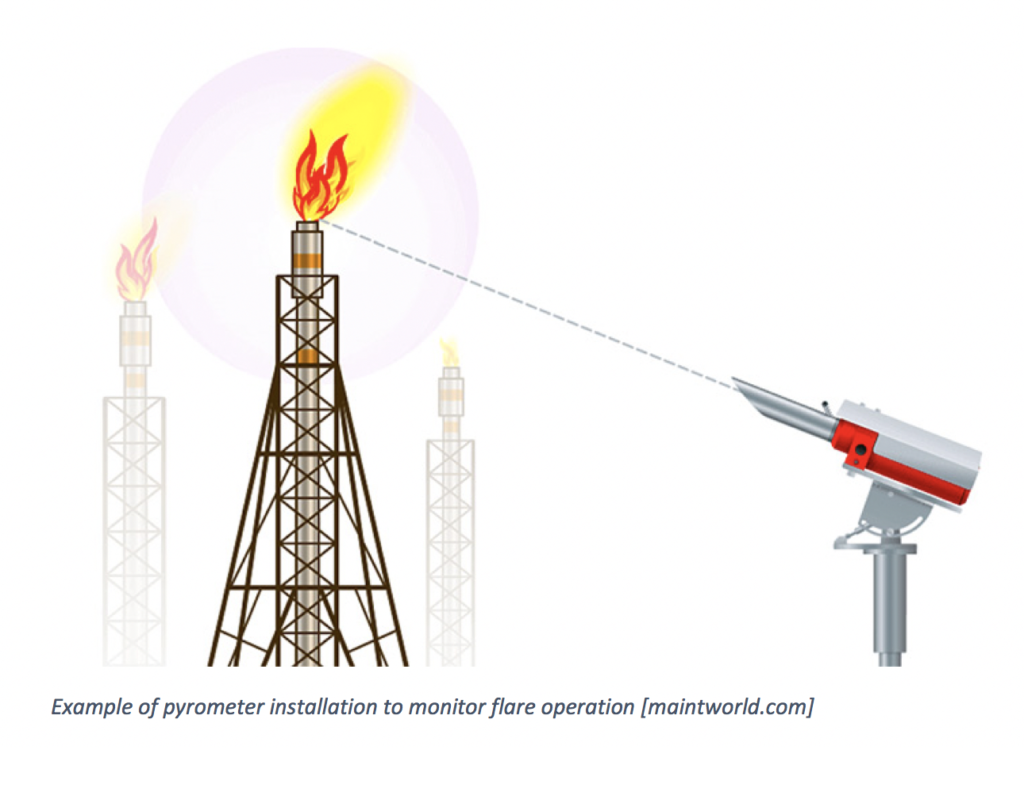

A pyrometer provides a real-time measurement of the temperature of a distant source. This remote-sensing technology is based on changes in the intensity of light received by the observer. It is an optical system that works for various flare sizes and types. Typical application is the continuous flare or pilot monitoring, to confirm its operation. It is often used in combination with thermocouples for ensuring a redundant system. Temperature may be used as a proxy for combustion efficiency, where changes to the temperature may be indicative of lower efficiency – it is not a direct measure of methane emissions.

Advantages

No direct access/physical contact to source required

Distances up to ¼ mile (400 meters) possible

Applicable for various flare types: ground flares, elevated flares, offshore

Can either be permanently installed or as mobile device

Operates in range of conditions, day & night

Easy to install and upgrade existing facilities, scalable

Limitations

Does not directly measure methane

Needs a clear line of sight

Limited to temperature measurement only (typically used to confirm operation a pilot or a continuous flareA flare that is intentionally lit for the majority of the time, usually as part of the safety critical equipment on a facility Learn more... but no further details)

Monitoring of staged flares might require additional imaging technology/software

Some limitations in severe weather conditions (e.g. heavy fog/heavy rain)

Go Deeper

Case study

For efficient operation of a flare stack, additional monitoring with a pyrometer as redundancy for a thermocouple system is installed. This ensures safe operation, environmental assurance and governmental compliance at all time. In this example, pyrometry is used in a single flare tip application to detect if the pilot flame is on or off. In case the installed thermocouple fails, the pyrometer still provides a reliable mA signal if the pilot is working or not. This signal is then translated into a green or red light to show the operational status. While the thermocouple needs to be installed in a very challenging environment at the flare tip (high temperatures, corrosion, vibration), the pyrometer is located in a safe distance to the flare tip only requiring a clear line of sight, as illustrated in the picture below.

Spectrometry is the observation and measurement of wavelengths of light or other electromagnetic radiation. Once a range of wavelengths, or a spectrum, for a gas mixture has been measured, by observing the intensity or amplitude of individual wavelengths, the method allows for determination of chemical composition of that gas mixture. Spectrometry is typically performed with the use of a spectrometer which is an instrument that separates and measures the spectral components of the sample or object being studied. Various types exist, but the most used are either a mass spectrometer or an optical spectrometer. Spectrometry techniques may be used for process control - such as determining the composition of flared gas, or for environmental measurements such as determination of combustion efficiency.